Ammonium Bicarbonate Food Grade

General Information

Ammonium bicarbonate, NH4HCO3, is a common leavening agent which releases CO2 without the need for an acid. Unlike baking powder or soda, it does not leave an alkaline taste, characteristic of soda or baking powder.

Properties

- Colorless or white crystals

- Faint odor of ammonia

- Melting point: 95 °F (35 °C)

- Solubility: Freely soluble in water. Insoluble in ethanol

- Decomposes above 34 °C with formation of ammonia gas

Specification

Appearance:White, crystalline free flowing powder.

Content:99.5% ~ 101.0%

PH value:7.0-8.5

Chloride (as Cl):0.003% Max

Sulfate (as SO4):0.007% Max

Involatile Matters:0.05% Max

Arsenic:0.0002% Max

Heavy Metals (as Pb):0.0002% Max

Iron:0.002% Max

Sulfur (as S):0.0002% Max

Particle size:60-100mesh

Function

Ammonium bicarbonate can release ammonia and carbon dioxide, leavening gases without reacting with a leavening acid.2 It spontaneously decomposes into this ingredient and ammonia first and in a later step into ammonia and carbon dioxide gas:

Baking soda can replace this ingredient in low-moisture products like dry cookies or some cracker products although this may not reproduce the unique texture.

Application

Ammonium Bicarbonate is an important ingredient for various cookies and biscuits. Being a highly effective backing agent, ammonium bicarbonate does not leave any flavor-affecting residues. It always meets highest quality standards.

Advantages of using this in baked goods include:

• The absence of alkaline taste residue often encountered with sodium bicarbonate

• It doesn’t affect the pH of the baked goods

In high moisture baked goods (in excess of 5%), ammonium bicarbonate may lead to the development of ammoniacal flavor. This is why it’s most suited for low-moisture products such as biscuits, crackers, cookies, and waffle cones.

Typically, this ingredient is mixed in with the liquid ingredients to ensure its dissolution prior to incorporating into the dry mix. In some formulas, it is used in combination with 30-50% baking soda.

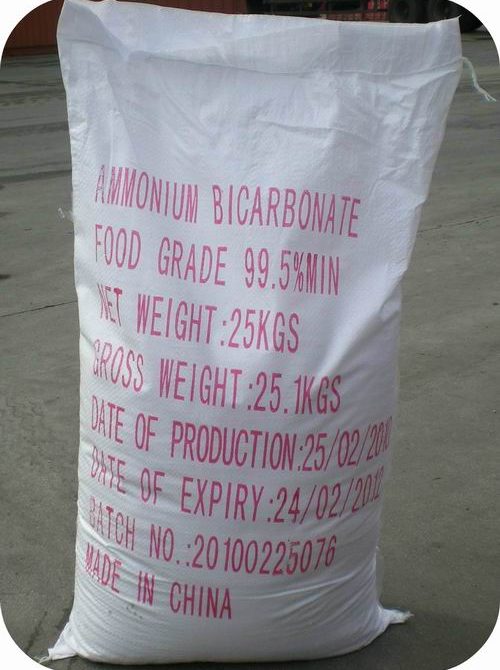

Packaging

• In 40kg fiber drum 18mts/20’FCL

• In 25 kg net in poly sack bags with inner polyethylene bag 25-27mts/20’FCL